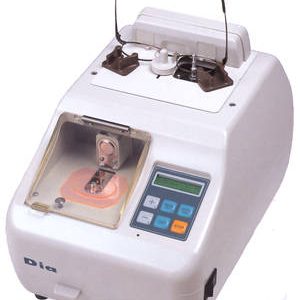

DIA E1000

E1000 SERIES MULTIFUNCTIONAL PATTERNLESS LENS EDGERS

State-of-the-art vertical wheel technology with 3D lens sensor and high definition large color touch-screen graphic interface enable more accurate, faster and more reliable jobs on any style, material and power of lenses.

5” x 7” Color touch-screen graphic interfaces

Make E1000 Series Edgers the fastest and easiest machines to use of learn! All relevant job information is displayed in 13 multiple languages.

Built-in 60 job memory is standard

Both the trace and process data are available to be stored and recalled within 60 jobs

• A small 18mm high lens with bevel, 16mm rimless lenses

• Shape modification (adjustment) software included

Advanced re-edge and finish options

Did you forget to polish, chamfer or groove the lens? You can still do it even if the lens was unblocked and data lost. Simply put a block on the lens anywhere and press the CHECK button on the touch screen, the E1000’s 3D Lens Sensor will measure the shape, thickness, curve and size of the lens-edge in the accuracy of 0.01mm and transfer those data to the re-edge program of computer.

Multi-width grooving and safety-beveling (E1000-GP, E1000-GP2)

Simple, durable arm grooves and safety-bevels. Simple adjustments for depth and width. Concurrent grooving and finishing with polycarbonate and Trivex lenses.

E1000 Edgers utilize an industrial motor and more aggressive wheels to achieve significantly faster result.

Flexible, axis-indexing lens blocks and chucks

allow faster processing and perfect axis on a wide range of lenses.

Yet, the E1000 Series and E920 Edgers include ”Self Lens-Trace”, which function copies a sample lens, another side lens or a pattern for finishing a lens simply without using any external tracer unit!

Chuck up the blocked Simply Layout the lens-shape sample lens. E1000’s with proper PD and MRP on sensor traces it to make the main screen then start the lens-shape data.

Simply Layout the lens-shape sample lens. E1000’s with proper PD and MRP on sensor traces it to make the main screen then start the lens-shape data. edging.

All models include:

All materials (Trivex, Poly, CR-39, Hi-index & Mineral Glass) Automatic and manual calibration Automatic and manual diagnostics Compact 35cm counter space (35 x 40cm, 70 x 40cm with tracer and blocker) Energy efficient (600 Watts or 5 Amps with industrial strength & speed) Hydrophobic coating friendly (Special processing programs available) Optional bar-code data entry Software memory module for easy upgrades User customizable operation menu VCA/OMA standard ready

| Diameter of lens acceptable | [Min]18mm high with bevel, 16mm high rimless finish / [Max] 100mm |

| Types of (fully- automatic) finishing available | Standard beveling / Rimless finishing / Wider beveling (GP2) / Standard bevel polishing (GP, GP2, P) / Rimless polishing (GP, GP2, P) / Front and rear safety bevel (GP, GP2) / Front, center and rear-face curve grooving (GP, GP2) |

| Bevel programs | Fully-automatic (computer controlled) beveling / Controlled beveling including front-face curve, optional curve and |

| Dimensions / Weight | 370(W) x 370(D) x 553(H) mm / 39 kg |

| Power requirement | 100-120V / 60Hz or 200-240V / 50Hz AC, 600W |

Designs and details can be changed without prior notice for the purposes of improvement.

Reviews

There are no reviews yet.